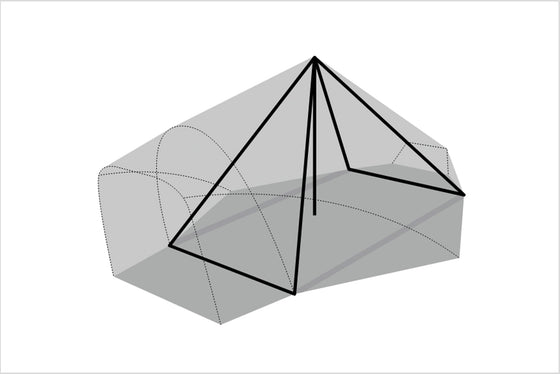

A hybrid two-room shelter that combined a one-pole and framework structures, making it simple to set up while creating a spacious interior.

Depending on the country or region, additional fees such as customs charges may be required upon delivery.

Instruction manual

GALLERY

FUNCTION

Simple Construction

Inner Tent Included

Spacious Room for 4 People

Inner Tent Also Opens on Both Sides

Fully Closable Panels

Broad Mesh Panels

No Dead Space

Front Visor

Flipping Up the Front Panel

FABRIC

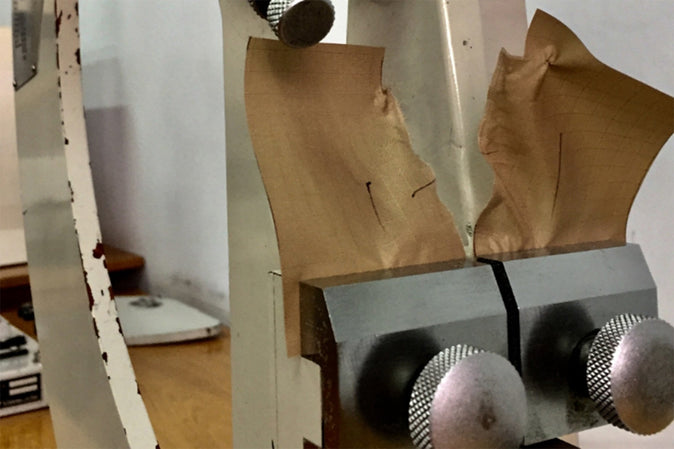

This tent is made of Ripstop Polyester fabric. By applying silicone on the front surface and polyurethane (PU) on the back surface, a high level of tear-resistance and waterproof performance has been achieved. Compared to the commonly used fluorine treatment for ordinary tents, shelters, and tarps the silicone treatment has the added benefit of significantly increasing tear-resistance, making it possible to use thinner and more lightweight fabric.

Water pressure resistance is kept at 1,500 mm for both 50D and 75D, suppressing fabric deterioration due to heat during PU processing and maintaining tear-resistance.

Fluorine coating only applies to the surface of a fabric having no effect to the strength, however silicone treatment penetrates into the fabric significantly increasing the tear resistance.

| ZANE ARTS | General Material | ||||

|---|---|---|---|---|---|

| FABRIC | 50D Polyester Ripstop | 75D Polyesters Taffeta | 75D Polyesters Taffeta | 150D Polyesters Ox | 210D Polyesters Ox |

| TREATMENT | Silicone / PU | Silicone / PU | Fluorine / PU | Fluorine / PU | Fluorine / PU |

| TEAR STRENGTH (vertical/side) | 1.95 / 1.15 kgf | 3.15 / 1.21 kgf | 0.72 / 0.53 kgf | 1.45 / 1.10 kgf | 1.65 / 1.28 kgf |

| WEIGHT | 66g /㎡ | 78g /㎡ | 72g /㎡ | 112g /㎡ | 126g /㎡ |

SPEC

Tent Body

Inner Tent

Floor : 150D Polyester Oxford・PU Treated (Water Resistance 1,500mm)

Center Pole

Frames

3m Rope

2m Rope

Carrying Case

Pole Case

Rope Case